Description

Specs

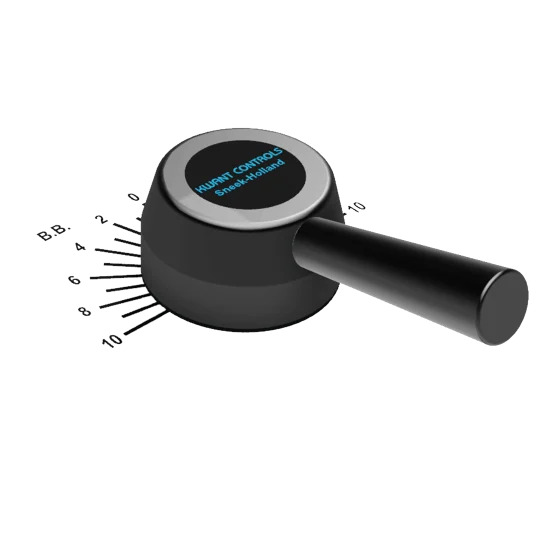

The RSCU-H96 and H144 come with potentiometers and/or micro switches for the electrical interface with the propulsion- and steering control systems. The default IP-rating is IP56, with the possibility to limit the speed lever travel and/or steering angle according to your requirements. Palpable stops (detents) can be supplied in both sections.

Both models are available with stepper servo motors, driven by either:

- An external Control Unit to Bus Interface module (‘CUBI’). This module is the interface to the (redundant) CAN bus, which forms the basis for the Electric Shaft system of the( fifth generation), ELAS-5. The CUBI also offers an (limited) amount of I/O for the human-machine interface i.e. signal lamps, pushbuttons and buzzers.

- Integrated CAN electronics (I-CAN) offering a direct CAN-Open machinery interface. This option requires the presence of a CAN bus master station.

IP level: IP56

All executions are type-approved by ABS, BV, CCS, DNV, LRS, NKK , RINA and RMRS.

Available output signals

- 5KOhm;

- 4-20mA;

- Integrated CAN;

Options

- Extra or special potentiometer(s);

- Micro switch contact(s);

- Customized grips (other materials like wood), logo’s;

- Stepper motors for:

- Automatic line-up (Electric Shaft);

- Electrical fine adjustment;

- Haptic feedback;

- Programmable detents (palpable stops);

- Limited lever travel;

- Other options on request.

The RSCU-H series consist of three members in the following executions:

- RSCU-H96 (96x96mm);

- RSCU-H144 (144x144mm);

As their names already suggest, the main difference is the size of the top plates. The RSCU-H96 bottom section has been designed as a machined aluminium block. The RSCU-H144 is composed more traditionally and therefore allows more variations when it comes to machinery interfaces. They both share the recognizable cylinder shaped control head, identical to that of the BUK-H propulsion levers.